Categories

Vacuum Assisted Priming Centrifugal Pump

How It Works

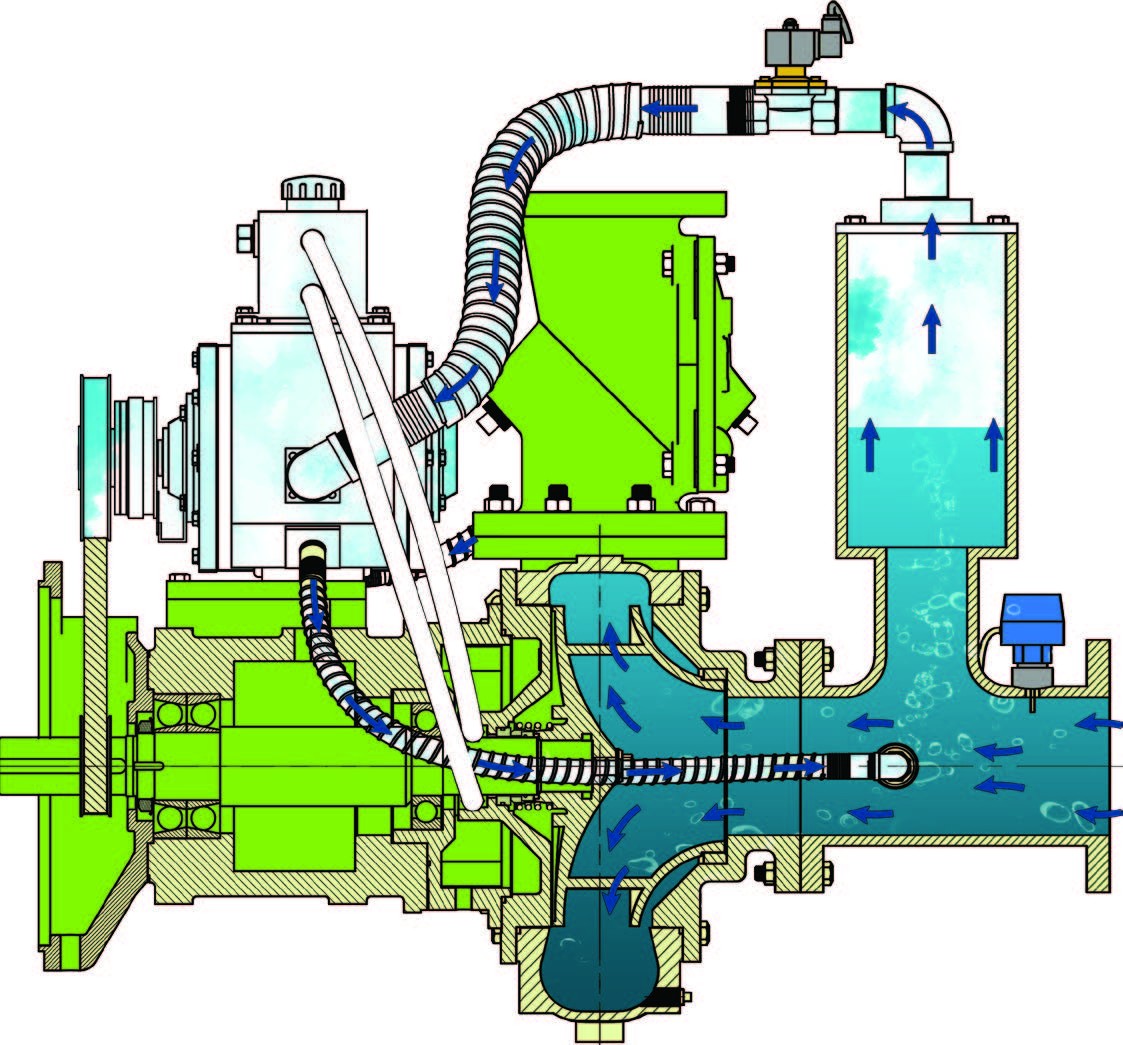

A vacuum-assisted self-priming centrifugal pump is made up of two pumps, an end suction or split casing pump and a diaphragm pump. When there is no water in centrifugal pump, the diaphragm pump will operate to remove air out of the suction line until the pressure in suction line is less than atmospheric pressure which allows liquid to flow into pump. When there is sufficient water in the pump, which means it’s primed and ready to pump, diaphragm pump continues to operate on low power until it’s required again. If pump ever loses prime or there is no liquid left, the process starts automatically again.

Why It Is Advantaged

ECO Friendly Vacuum Priming System

| The self-priming system utilizes a specially designed 3rd generation vacuum pump technology. It enables any centrifugal pump finish priming within seconds to tens of seconds. It has extraordinary features like large air process capability, high vacuum, low operation temperature, maintenance free, oil and mechanical seal free etc, which sets up a new benchmark in self-priming pump market. |

Auto Switch System

| The self-priming system will be switched to sleep status automatically once priming was finished. When it is used for general purpose application, self-priming system only operates for a few seconds for priming, and which makes it almost unnecessary for daily maintenance or changing spare parts at its life cycle. |

| |

Dry Running Protection System

| Vacuum assisted priming pumps can run dry for a long time without damaging its mechanical seal due to its dry running protection system, which consists of a normal mechanical seal, an oil chamber and an oil reservoir. The oil chamber and oil reservoir are connected by two hoses and forms an oil circulating loop. As an option, the mechanical seal stationary seat can also be made with an air cushion designed surface which eliminates the use of oil lubrication in case of pump’s long time dry running. We can also use a set of lip seals to replace the mechanical seal as option 2, and it makes the sealing result even better and subsequent maintenance easier. |

| |

Cooling System

| A pressurized cooling flush water is introduced from centrifugal pump’s water passage through an access port into vacuum pump’s water jacket which contains the entire vacuum pump. Cooling water flows into the water jacket from one side through a suction hose and discharges from the other side, then returns back to the centrifugal pump’s suction side through a discharge hose. Pressurized flushing water cools the vacuum pump quickly and brings most of the heat out of the vacuum pump’s cavity, which keeps the vacuum pump run at a very low temperature and makes the self-priming system an extraordinary long life. |

| |

Easy Disassembling Structure

| It is very convenient to remove the vacuum pump’s cover from its non-drive end, and slides can be easily pulled out for inspection or replacement. It is also easy to access to the centrifugal pump’s impeller, wear ring or mechanical seal for inspection or maintenance without removing diesel engine or pump’s frame since the centrifugal pump’s suction cover can be fully opened. |

| |

Non-clogging Impeller Design

| All the solids handling vacuum assisted priming pumps were designed with a wide water passage impeller which allows solids with 3” diameter or larger pass through the impeller easily. Vacuum assisted priming pumps can be widely used in any critical application like sewage, sludge and even processing fluid with large size stones. |

| |

Self-cleaning Function

| Vacuum assisted priming pump’s stuffing box was designed with a special structure to mix and discharge solids. Any small size solids or sands entering into the stuffing box will be mixed by the mixers located on the wall of stuffing box, and then be discharged to the outside of the stuffing box with the centrifugal force generated by the impeller back vanes. This self-cleaning function keeps the mechanical seal spring from clogging by any solids or sands accumulated inside of the stuffing box efficiently so as to avoid any mechanical seal failure. |

| |

Proven Technology

| Vacuum assisted priming pumps own multiple proven technologies. Because of self-priming system’s powerful function, they can be used in almost all aspects of fluid industry, such as Dewatering, By-Pass, Fire-Fighting, Lift station back-up system, mining, irrigation, water transfer and well point system etc. |

Eco-friendly Drain Collector Base

| Attenuated pump base was designed to contain any possible leakages from pump, engine or from internally installed fuel tank. A drainage port and plug are available for easily draining the leaked liquid. All pump base was designed with a large internal space so as to contain min. 110% of the total capacity of the diesel tank and all engine fluids. |

| |

Air-water Isolator

| Vapor is normally generated during vacuum pump’s evacuation, and then becomes either water or ice staying inside of the vacuum pump when ambient temperature is low. The accumulated water or ice is a big threat to vacuum pump especially in cold area, so an air-water isolator is suggested to be installed in every pump to collect the vapor/water before it enters into the vacuum pump. |

Auto Start/Stop Control

| Remote control is available when a water level sensor is installed on the pump so as to control the pump’s start/stop automatically. A state-of-the-art microprocessor-based digital engine control monitors all engine functions including alarms. The control panel features and easy-to-read 32-character display. It is ideal for conserving fuel, avoiding engine overhauls and comes standard on all vacuum assisted priming pumps. |

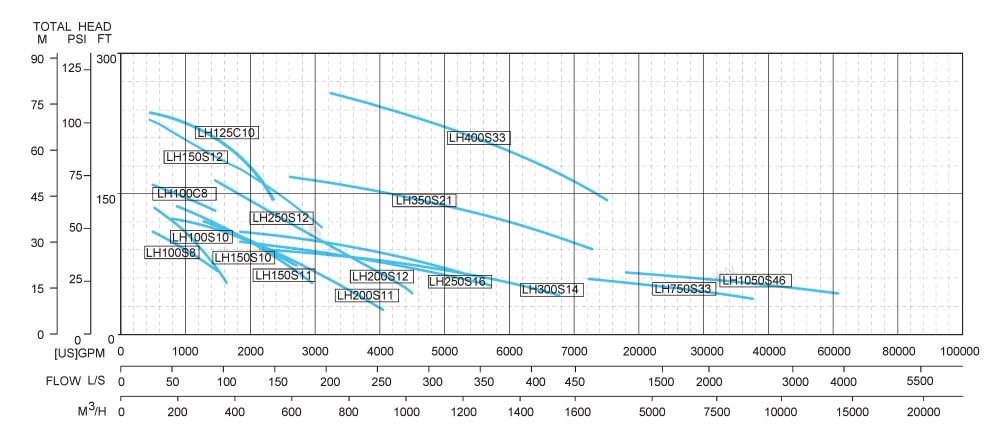

Selection Chart and Performance Range

Low-Head

Model | Suct. size | Disch. size | Impeller dia. | Max. flow | Max. head | Max. solids | RPM up to | Model | Suct. size | Disch. size | Impeller dia. | Max. flow | Max. head | Max. solids | RPM up to |

LH100S8 | 4 | 4 | 8 | 1400 | 120 | 3 | 2200 | LH300S15 | 12 | 12 | 15 | 6600 | 108 | 4 | 1250 |

LH100S10 | 4 | 4 | 10 | 1700 | 150 | 3 | 2000 | LH350S21 | 14 | 14 | 24 | 12320 | 200 | 3.58 | 1000 |

LH150S10 | 6 | 6 | 10 | 2600 | 168 | 3 | 2200 | LH500S39C | 20 | 20 | 39 | 20680 | 183 | 5.98 | 585 |

LH150S11 | 6 | 6 | 11 | 2700 | 160 | 3 | 2000 | LH600S33A | 24 | 24 | 33 | 26400 | 107 | 6.5 | 585 |

LH200S11 | 8 | 8 | 11 | 4400 | 145 | 3 | 2000 | LH750S33A | 30 | 30 | 33 | 37400 | 65 | 8 | 485 |

LH200S12 | 8 | 8 | 12.25 | 4400 | 170 | 3 | 1800 | LH1050S46B | 42 | 42 | 46 | 66000 | 85 | 9.8 | 360 |

LH250S12 | 10 | 10 | 12 | 5280 | 116 | 4 | 1800 |

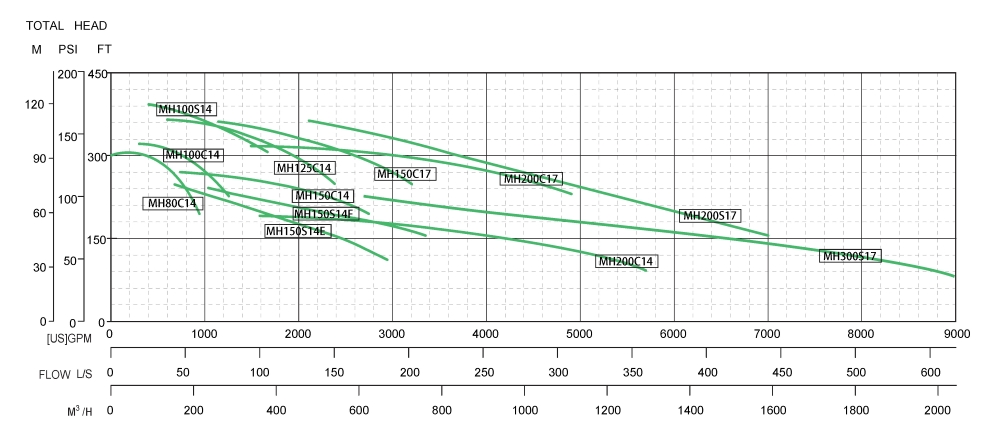

Medium-Head

Model | Suct. size | Disch. size | Impeller dia. | Max. flow | Max. head | Max. solids | RPM up to | Model | Suct. size | Disch. size | Impeller dia. | Max. flow | Max. head | Max. solids | RPM up to |

MH100S14 | 4 | 4 | 14 | 1650 | 425 | 3 | 2300 | MH80C14 | 5 | 3 | 14 | 950 | 354 | Clean | 3000 |

MH150S14F | 6 | 6 | 14 | 3100 | 270 | 3 | 2000 | MH100C14 | 5 | 4 | 14 | 1260 | 340 | 3000 | |

MH150S14E | 6 | 6 | 14 | 3000 | 290 | 3 | 2000 | MH125C14 | 6 | 5 | 14 | 2376 | 340 | 2500 | |

MH200S17 | 10 | 8 | 17 | 6800 | 440 | 3.5 | 2000 | MH150C14 | 8 | 6 | 14 | 2700 | 280 | 2100 | |

MH300S17 | 12 | 12 | 17 | 9000 | 300 | 3.75 | 1780 | MH200C14 | 10 | 8 | 14 | 4750 | 175 | 1800 | |

MH150C17 | 8 | 6 | 17 | 3168 | 370 | 1900 | |||||||||

MH200C17 | 10 | 8 | 17 | 4900 | 320 | 1800 |

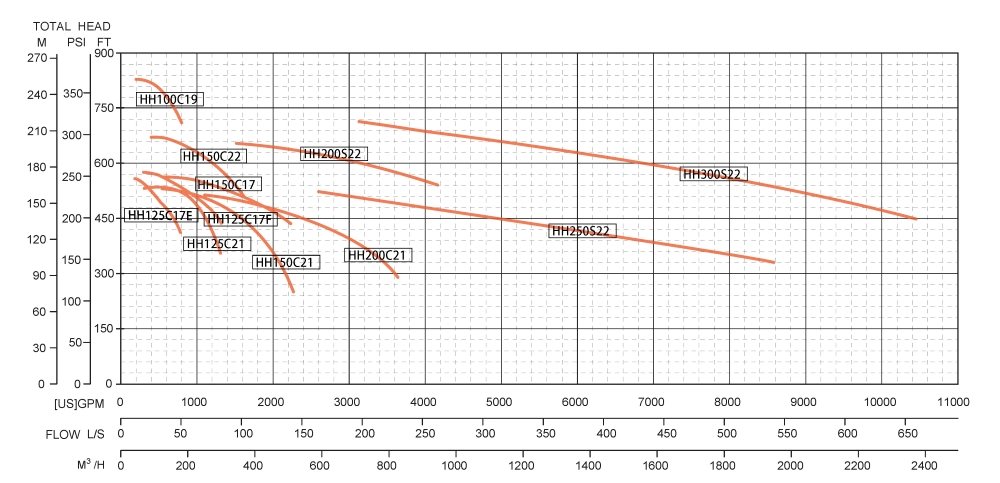

High-Head

Model | Suct. size | Disch. size | Impeller dia. | Max. flow | Max. head | Max. solids | RPM | Model | Suct. size | Disch. size | Impeller dia. | Max. flow | Max. head | Max. solids | RPM |

HH100C19 | 4 | 3 | 19 | 800 | 800 | Clean | 2400 | HH150C17 | 6 | 5 | 17 | 2100 | 550 | Clean | 2300 |

HH125C17E | 5 | 3 | 17 | 880 | 564 | 2300 | HH150C21 | 6 | 5 | 21 | 2200 | 530 | 1800 | ||

HH125C17F | 5 | 4 | 17 | 1260 | 557 | 2300 | HH200C21 | 8 | 6 | 21 | 3500 | 510 | 1800 | ||

HH125C21 | 5 | 4 | 21 | 1200 | 520 | 1800 | HH200S22 | 8 | 6 | 22 | 4200 | 640 | 2 | 1900 | |

HH150C22 | 6 | 4 | 22 | 1650 | 600 | 1900 | HH250S22 | 10 | 8 | 22 | 8400 | 590 | 4 | 1800 | |

HH300S22 | 12 | 8 | 22 | 10560 | 780 | 3 | 2000 |

Application

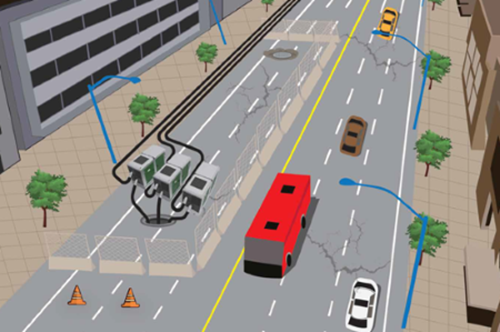

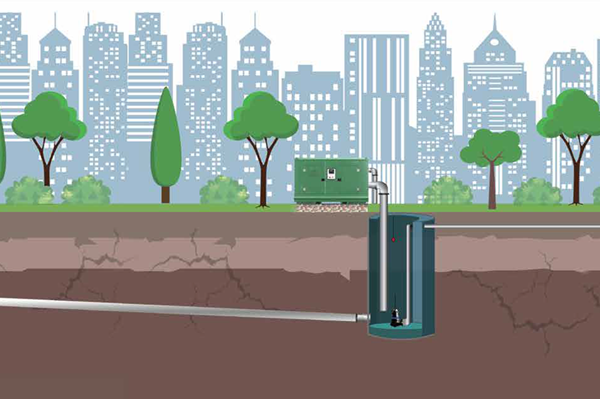

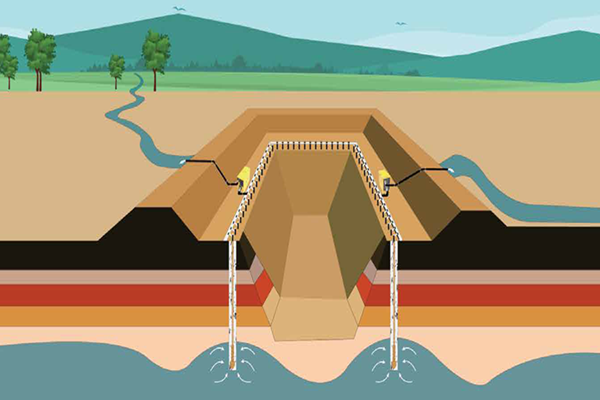

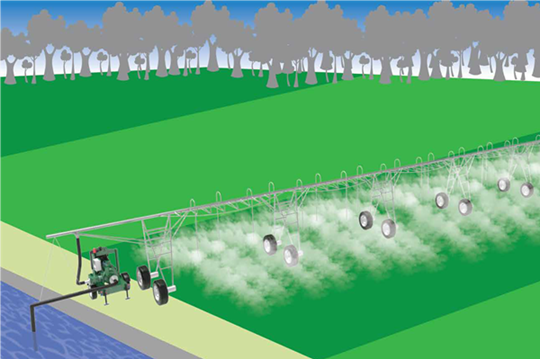

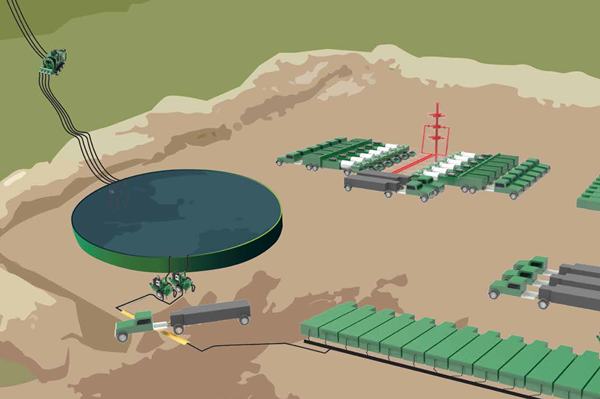

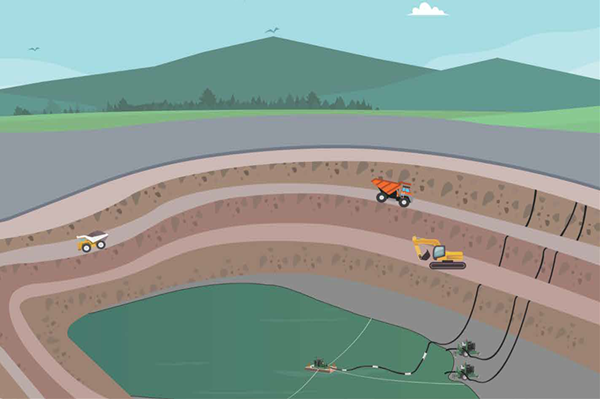

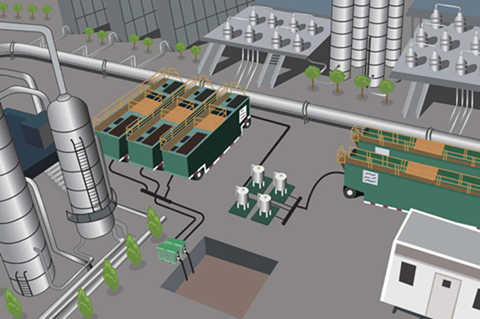

Emergency Flood Control, Water Drainage |  Rush Repair, Extension, Parallel In, Relocation of Pipe Network |  Emergency Fire Fighting |  Emergency Movable Pumping Station |  Water Control of Civil Construction |

Modern Agriculture |  Well Drilling, Hydrofracturing |  Water and Sewage Drainage of Mines |  Water Environment Treatment |  Industrial Wastewater Treatment |