Categories

As an end-suction, side-discharge, mixed-flow, non-clog pump, MN/MF series are designed and engineered for reliability, low cost and long life in demanding sewage handling services or where solids in suspension are of particular concern.

Advantages

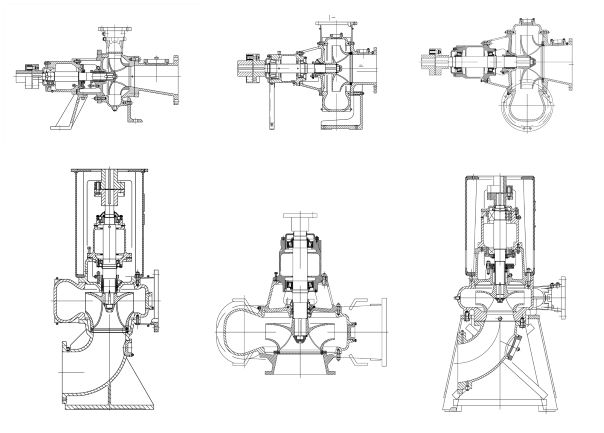

| Flexibility | Configurations And Motor mounts | lHorizontal end suction MN-motor mounted on common baseplate lVertical with supportive base elbow MNC-motor mounted on pedestal MNV-motor mounted on separate floor lVertical with bottom suction MNF-motor mounted on pedestal MNZ-motor mounted on separate floor lHorizontal end suction MF-motor mounted on common baseplate lVertical with supportive base elbow MFV-motor mounted on separate floor MFC-direct connected motor |

| Nozzle orientation | Variety of nozzle positions to suit most piping arrangements without special or costly modifications | |

| Reliability | Robust construction Special materials | lMinimal shaft deflection with oversized shaft and reduced overhang virtually eliminating shaft failure and increasing packing or seal life lConservative bearing design arranged to eliminate all radial and axial play lReplaceable hardened chrome steel wear rings on impeller and suction head to extend pump life lHardened chrome steel shaft sleeve standard lSupports to minimize vibration and assure rigidity |

| High Efficiency | Broad hydraulic range Reduced power consumption | lMaximum solids handling capabilities lWide range of efficient operation and reduced power consumption lAdjustable wear ring clearance for continued high efficiency |

| Easy maintenance | lEasy access to stuffing box through large openings in the bearing housing support lRemovable gland for easy packing adjustment or replacement lStuffing box arranged for either grease or water seal lWide variety of mechanical seal options lBack pullout of entire rotating assembly without disturbing the casing or suction and discharge piping lReadily accessible lubrication points in bearing housing | |

| Complementary design | lDry-pit, solids-handling lVertical, wet-pit lSubmersible non-clog | |

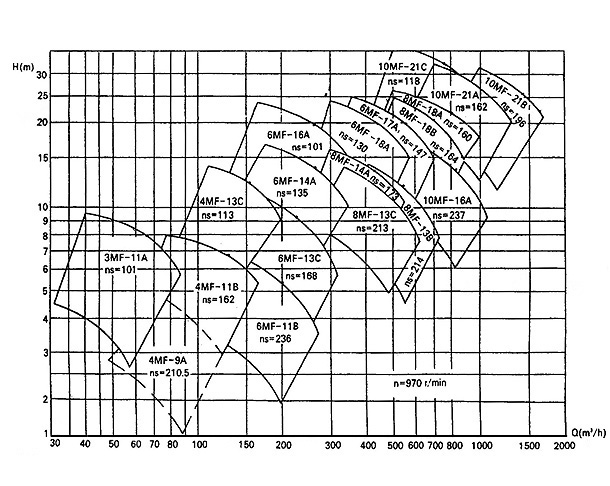

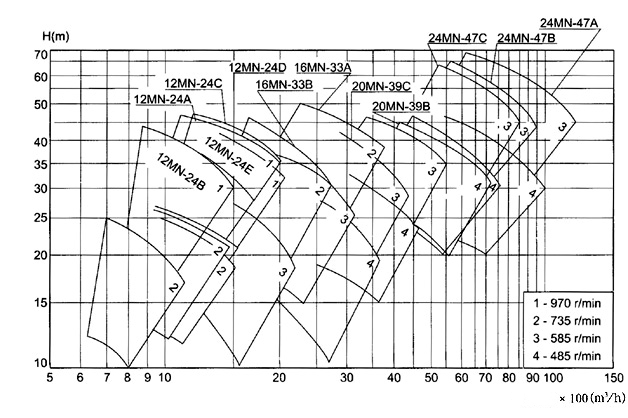

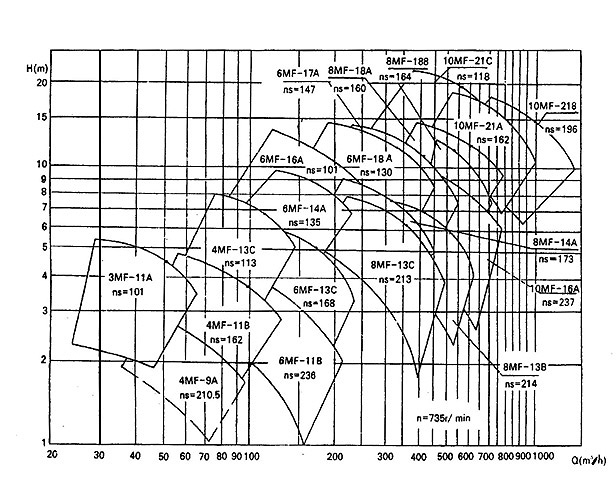

Operating Range

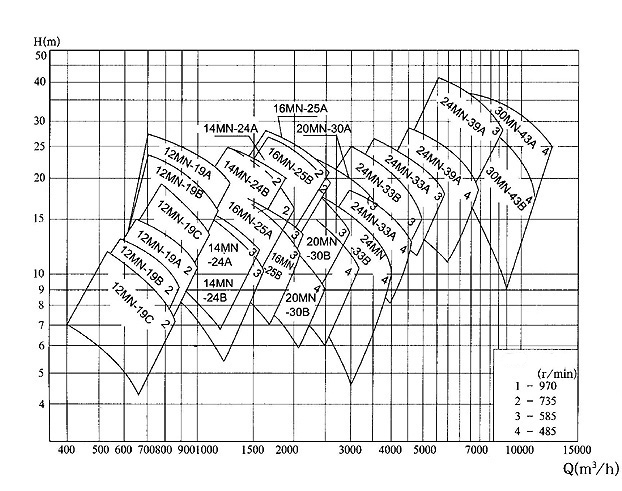

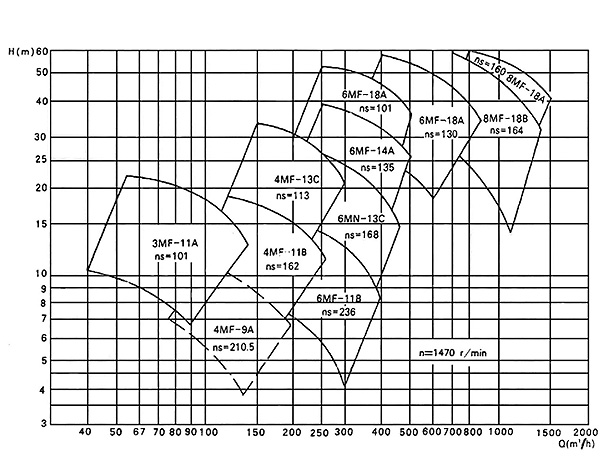

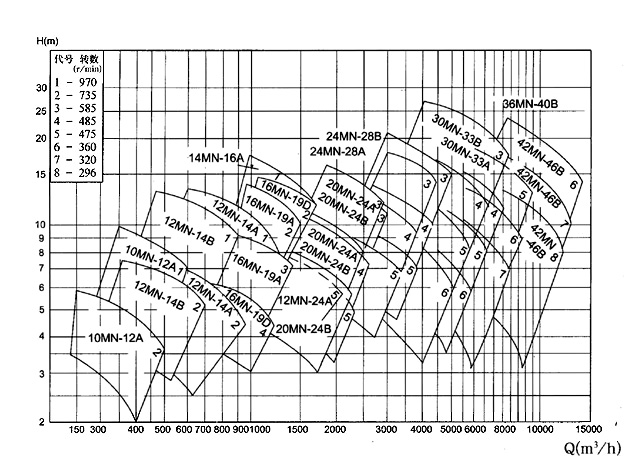

MN Flows up to 45 500 m3/h (200 000 gpm) Heads up to 90 m (300 ft) Sizes up to 1800 mm (10-72 in) Solids size up to 249mm (9-4/5 in) | MF Flows up to 2275 m3/h (10 000 gpm) Heads up to 90 m (300 ft) Sizes up to 400 mm (3-16 in) Solids size up to 152mm (6 in) |

|  |

|  |

|  |

Material Construction

Main Part | Standard | Option |

Casing | Cast iron | 1.5% Ni Cast iron |

Impeller | Cast iron | 1.5% Ni Cast iron |

Stuffing box frame | Cast iron | 1.5% Ni Cast iron |

Bearing frame | Cast iron | Cast iron |

Shaft | Cast steel | 13% chrome steel |

Sleeve | 13% chrome steel | 13% chrome steel |

Other options as per requirement.

|  |  |