Understanding the Basics of Fire Pumps

Jan 05, 2022|

Jan 05, 2022| View:686

View:686A fire pump is any type of purpose-driven pump used within a fire protection system. It can be driven by diesel engines, electric motors or even steam and is used to provide increases in water pressure to meet the design requirements of a fire protection system. Fire pumps do not create a water supply. Instead, they create pressure from an existing water supply, such as a city supply line or a storage tank, by converting mechanical energy into hydraulic energy.

Fire pumps are necessary when the water supply available does not generate the necessary hydraulic pressure required to meet demand of a fire protection system such as automatic sprinklers and standpipes, or even foam systems. An example would be a high-rise building where the pressure from a city supply line is not great enough to overcome gravity to reach the top of the building. In this instance, installing a fire pump is done to provide a boost to get the necessary pressure to the top. It is important to remember to have a steady supply of water so that the fire pump may operate correctly.

When it comes to best practices for fire pump design and installation, the National Fire Protection Association (NFPA) 20 Standard for the Installation of Stationary Pumps for Fire Protection provides the guidebook. NFPA 20 provides guidance for fire pumps and their installations but does not provide listings and defers to the authority having jurisdiction (AHJ) as the entity with the final say on installations. The AHJ could be the local fire chief or it could be the insurer—it depends on locale.

With regard to listings, groups such as Underwriters Laboratories (UL) and Factory Mutual (FM) provide UL Listings and FM Approvals on products that meet their testing requirements along with their own individual publication standards, UL448 and FM1311. NFPA 20 does not provide listings or approvals but acts as the guide for best practice. If a fire pump has the UL and FM stamp of approval, the manufacturer has gone through the most stringent requirements to be able to provide their pumps for fire protection, giving peace of mind that the pump will operate when it is needed.

NFPA 20, UL and FM provide guidance on the basic requirements fire pumps must meet to be considered as such. Each fire pump must be tested and meet the following requirements before it can be shipped, with a certified factory test curve being provided.

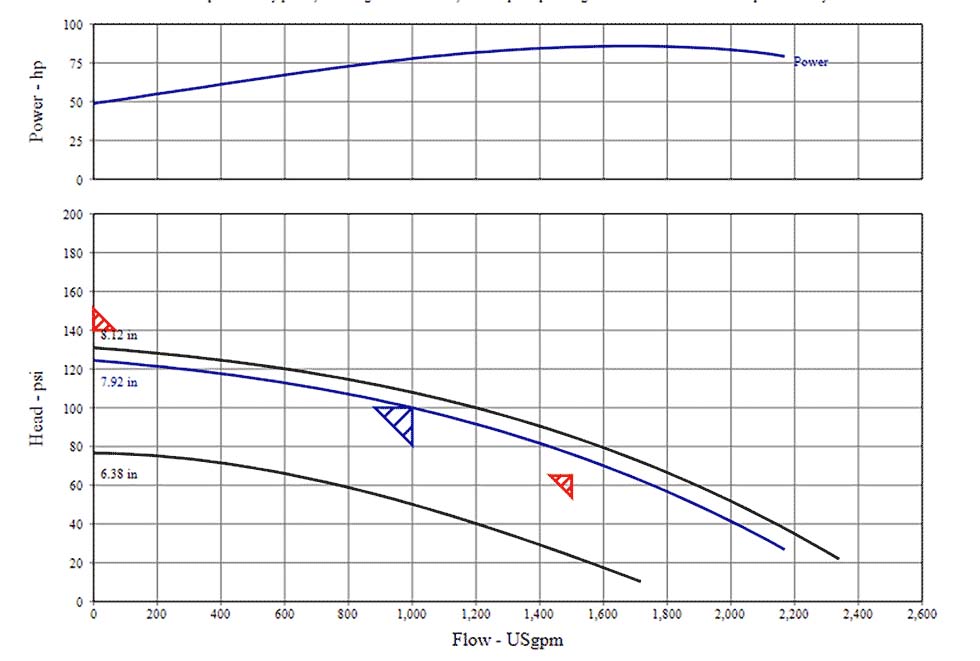

The first requirement is to have a rated duty point, which consists of the rated flow (gallons per minute [gpm]) and the rated pressure (pounds per square inch [psi]). Second, the fire pump must be able to meet 150% of the rated duty gpm while maintaining at least 65% of the rated duty point pressure. Third, the dead head, or churn pressure (pressure at no flow), must not be more than 140% of the rated duty point pressure. It should be noted that FM also requires a constant rise to shut off, which means the pump pressure must always be increasing as pump flow is reduced.

Finally, the driver of the fire pump, whether it is an electric motor, diesel engine or steam turbine, must be sized to meet the full horsepower demands of the fire pump, even if it means flowing beyond the 150% required duty point. The best way to ensure that the driver is sized correctly, and conforms to UL and FM requirements, is to review the certified factory test curve.

Look at the horsepower curve on the factory-certified test report and ensure that the power curve peaks and then begins to fall. This peak represents the highest amount of power the pump requires and the driver must be sized to meet that requirement. If the power curve is continuing to rise, the pump has not been tested to the full requirements of UL and FM, and the motor could be undersized and in violation of UL and FM.

An example of these requirements would be a fire pump UL Listed and FM Approved for 1,000 gpm at 100 psi, using an electric motor. The 150 psi at 65% point would be required to flow at 1,500 gpm while maintaining a minimum pressure of at least 65 psi. The 140% churn pressure must be less than 140 psi at 0 gpm. The pump curve (Image 1) shows a constant rise to shut off from the rated point to churn. The horsepower curve shows a peak of 86 brake horsepower (BHP) at 1,600 gpm, signaling that pump power peaks at 160% and requires a 75-hp electric motor. Many UL fire pump motors allow for a 1.15 service factor, so for this instance, a 75-hp motor provides 86.25 BHP.

Overall design and operation of fire pump installations have not changed much in the past few decades, save for some innovation on controls and other incremental improvements. However, recent developments in the industrial internet of things (IIoT) space have led to offerings that are changing the information users can glean from the fire pump and the entire fire protection system, leading to safer, more informed systems.

Up until recently, users only knew if the fire pump was on from a remote alarm but had no idea what it was actually doing. Was it flowing water or running at dead head? Was overall flow increasing over time in a fire event or had it plateaued, signaling the fire had been contained? How often was the pressure maintenance (jockey) pump running, and was there a potential leak in the system? What is the pump room temperature and is the system at risk of freezing?

Recent weather events in Texas caused many systems to freeze and break, leading to costly replacements—temperature monitoring and alerts could have helped with early action and prevention.

These were all unanswerable questions before IIoT remote monitoring solutions came to the forefront for fire pump systems. Now they are readily available, making for a more informed fire protection manager.

Source: https://www.pumpsandsystems.com/understanding-basics-fire-pumps