Categories

Our VL/VLH series are suitable for a variety of marine and industry applications, including seawater cooling systems, low temperature cooling systems, high temperature cooling systems, ballast water pumps, fire pumps, Seawater desalination, petrochemical , coal chemical process ,scrubber systems and exhaust Gas Cleaning.

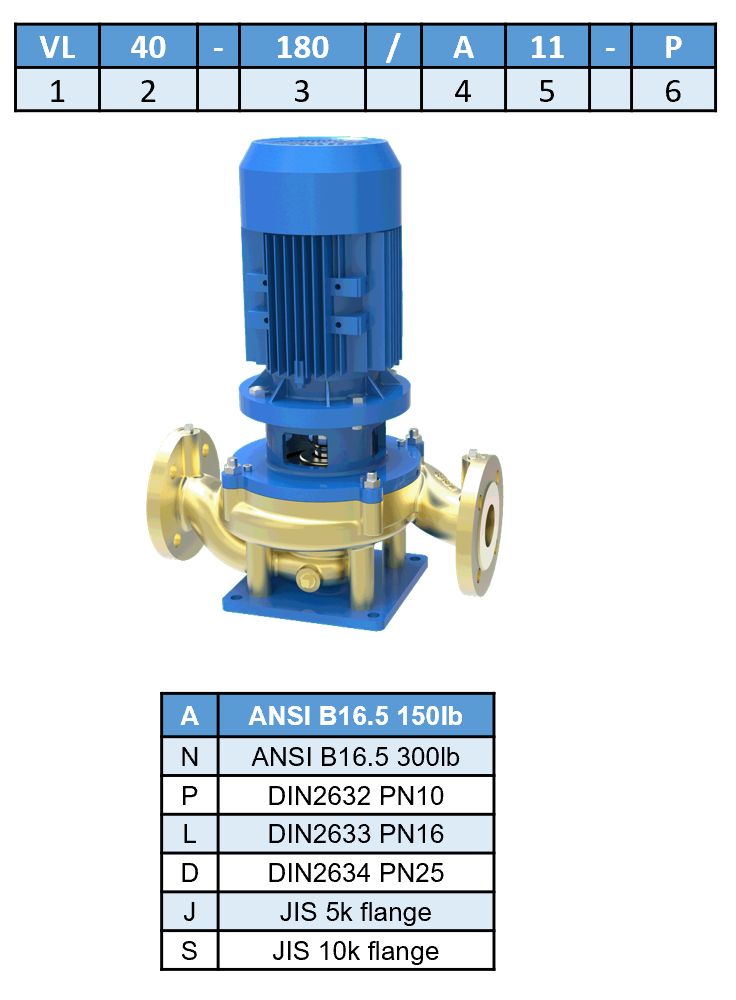

1 - PumpType

•VL:Verticalpipelinepump

•VLH: Horizontal end suction pump (parts are common with VL pump except for pump casing)

2 - DischargeNozzleNominalDiameter(mm)

•Dischargenozzledia.40mmNote:EqualInlet&outletdia.forimpellerdia. ≤330mmasstd.design

3 -ImpellerNominalDiameter(mm)

•Impellernominaldia.180mm

4 -MaterialCode(see below)

5 -CodeofPumpConfiguration

11:No bearing at pump end

12:Impellerrearslidebearing

13:Impellerrearanti-frictionbearing

15:Impellerrearslide&anti-frictionbearing

6 -CodeofInlet&Outletflangeratings

Note:FactoryflangestandardisP,whichistobesuppliedbydefaultincaseflangeratingsarenotmentionedintheorder.

Material Code | Pump casing and rear cover | Impeller | Shaft |

A | Cast iron GG25 | Aluminum bronze CC482K | Chrome steel 2Cr13 |

Q | Ductile GG40 | Aluminum bronze CC482K | Chrome steel 2Cr13 |

D | Tin bronze (RG5) | Aluminum bronze CC482K | ASTM 329 |

G | Cast steel (WCB) | Aluminum bronze CC482K | Chrome steel 2Cr13 |

R | ASTM 304 (CF8) | ASTM 304 (CF8) | ASTM 329 |

S | ASTM 316 (CF8M) | ASTM 316 (CF8M) | ASTM 329 |

Z | Silicon brass (HSi80-3) | Silicon brass (HSi80-3) | ASTM 329 |

L | ASTM 316L | ASTM 316L | ASTM 329 |

N | Nickel aluminum bronze CC482K | Aluminum bronze | ASTM 329 |

F | SAF2507 (1.4410) | SAF2507 (1.4410) | ASTM 329 |

T | Tailor-made | Tailor-made | Tailor-made |

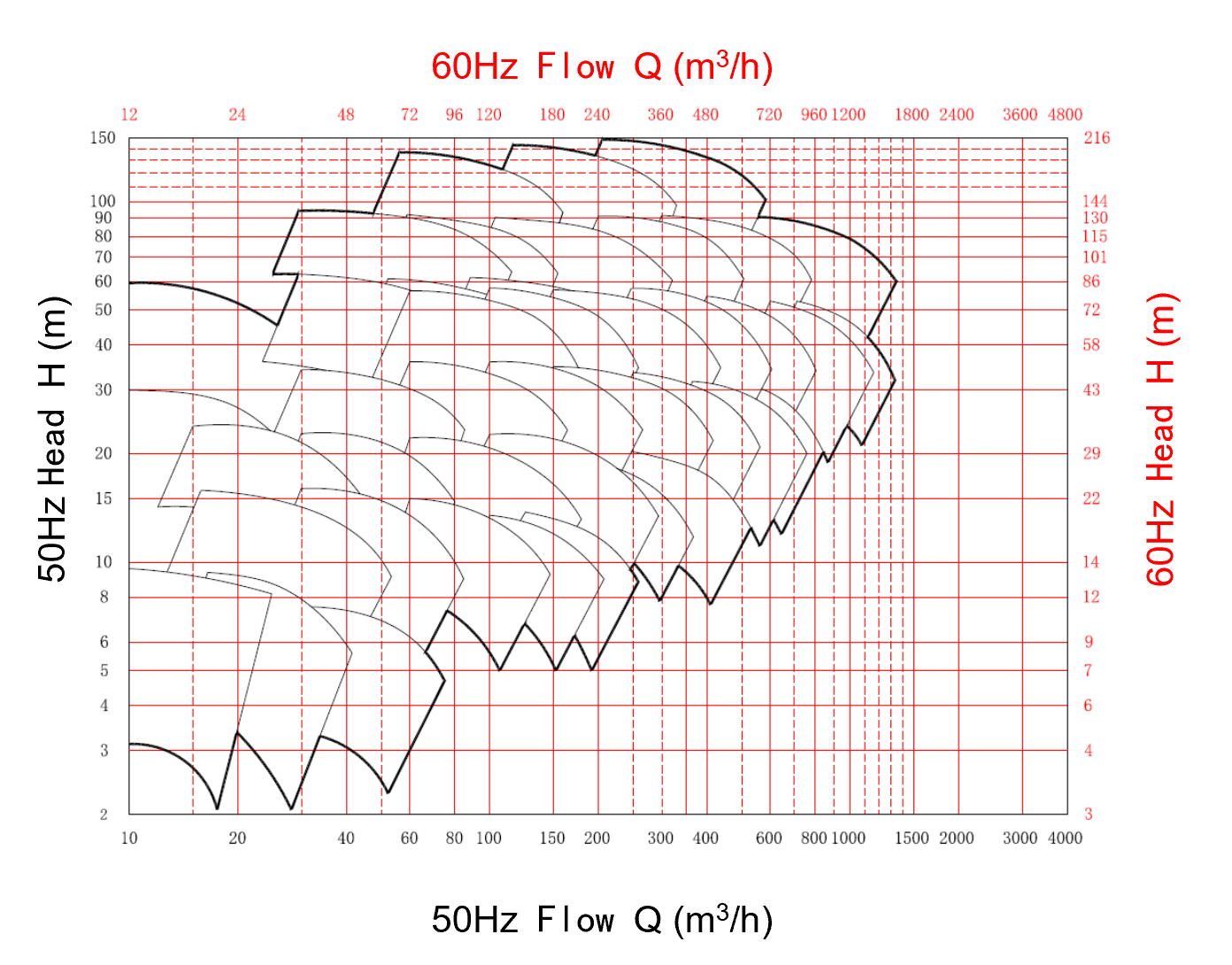

50 Hz | 60 Hz |

Head range: | Head range: |

5 - 150 m | 5 - 220 m |

15 - 500 feet | 15 - 720 feet |

Flow rate range: | Flow rate range: |

2 - 1500 m3/h | 3 - 1800 m3/h |

9 - 6600 US GPM | 13 - 7900 US GPM |

Medium temperature range: | |

Features, Benefits and Core Technology

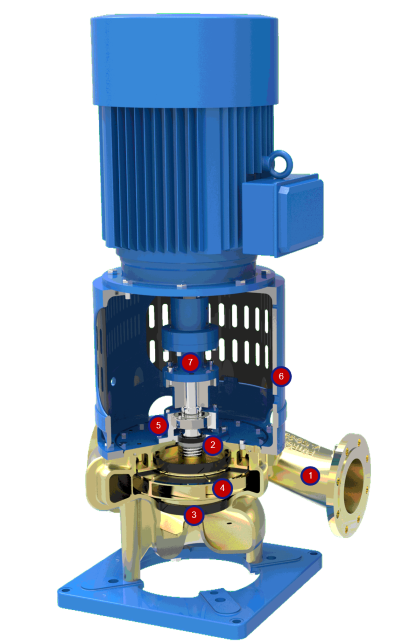

①Pump casing

lDouble volute design significantly reduces the radial force and the weight of the pump. The weight is reduced by up to 30% compared to well-known international marine pumps;

lMultiple materials available;

lHorizontal installation available;

②Mechanical seal

lVarious mechanical or packing seal available;

lMax. temperature of the mechanical seal structure is up to 220℃;

lPatented anti-particle mechanical seal protection;

③Wear ring

lMultiple materials available to ensure the longest service life and lowest wear

④Impeller

lOptimized hydraulic model (high-order equation G2-A surface design method) to improve efficiency and cavitation performance; in conformance with MEI0.7 European energy-saving standards; efficiency is about 5% higher than well-known international marine pumps;

lModularized for vertical self-priming pump configuration;

⑤Bearing

lModular configuration of heavy-duty and light-duty bearings is optional, without changing pump and motor stand size, and is always easy to maintain.

⑥Motor stand

lThe unchanged stand is used for all configuration options, such as heavy load, light load, single mechanical seal, double mechanical seal, self-priming, while keeping high stability and frame structure without affecting site installation;

lThe height of the motor stand is about 20% lower than that of other manufacturers, and the removal of the pump seal and impeller does not require the removal of the motor stand;

⑦Coupling

lEasy to maintain due to the design of coupling with intermediate joint

High reliability:

lShorter pump height to significantly reduce vibration and noise;

lImported high-performance composite material for wear ring is optional to ensure the longest service life and lowest wear;

lDurability and service life are highly improved through optimized structure and precision processing;

Footprint and weight reduced:

lRe-optimization targeting marine service. Reducing the weight by up to 30% and reducing the product height by up to 20% compared to well-known international marine pumps;

High efficiency:

lEnergy-saving products by using optimized hydraulic model (high-order equation G2-A surface design method) to improve efficiency and cavitation performance; in conformance with MEI0.7 European energy-saving standards; efficiency is about 5% higher than well-known international marine pumps;

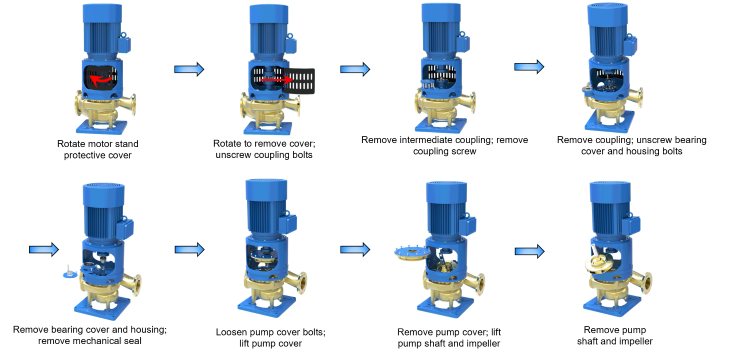

Easy to maintain:

lModular design; the main components of different structures (back cover, bracket, shaft, etc.) are interchangeable. Altering or upgrading the configuration only requires to replace the relevant parts module while keeping installation dimensions unchanged;

lMechanical seal and impeller can be replaced without disassembling the pump volute, motor or bracket. The maintenance time can be saved by about 50% compared with well-known international marine pumps;

Mechanical seal is standard configuration; double mechanical seal or packing seal is optional

Pump can be upgraded to common self-priming pump or strong self-priming pump for cavitation-prone installations

Double volute design greatly reduces the radial force of the pump and the weight of the pump casing

Illustration of Spare Parts Replacement